Dayanıklılığın, teknolojinin ve mühendisliğin kesişim noktasında: Aldem Çelik.

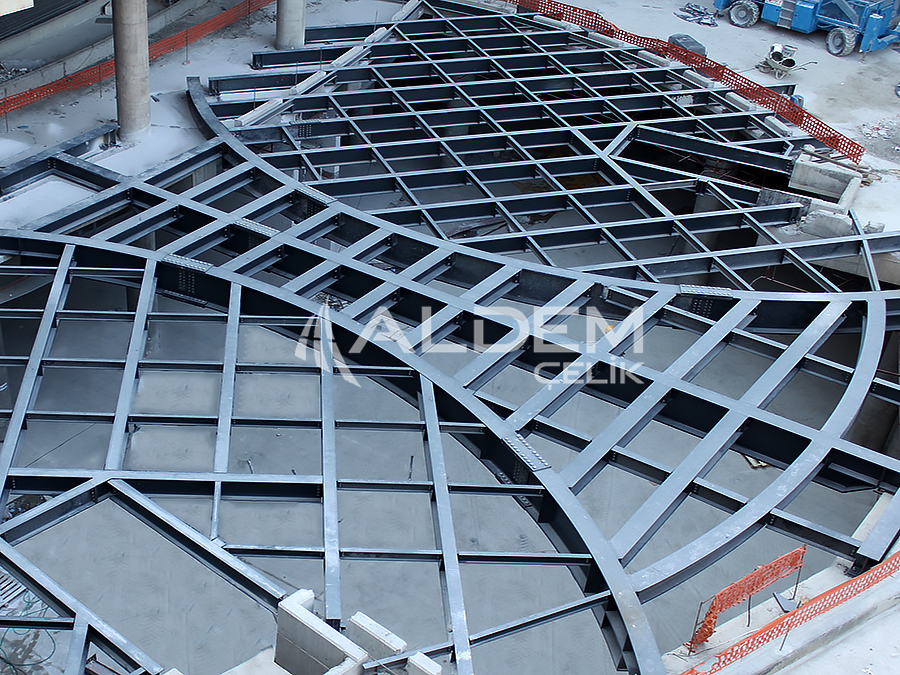

Steel Constructions

- Home

- Steel Constructions

Steel Constructions

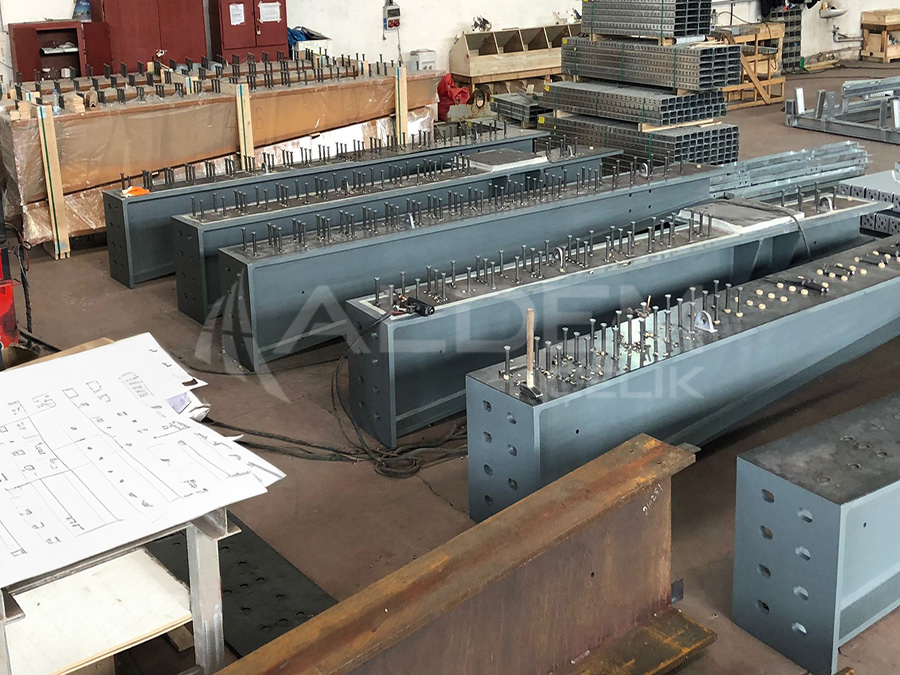

From Engineering to Implementation: Steel Structure Manufacturing to International Standards

Aldem Çelik develops steel structure solutions that provide maximum structural integrity for projects of any scale, from industrial plants to energy infrastructure. We don’t just build steel frameworks; we manufacture high-strength structural systems designed to meet all static and fatigue requirements of your project.

Expertise for Critical Structural Projects

Our competence in steel structures is built on our ability to meet the most demanding engineering specifications.

Certified Manufacturing Capability

All production processes are carried out under the mandatory European standard EN 1090-2 (EXC4). This ensures that every structural element we produce fully meets the intended load capacity and geometric tolerances.

Design-to-Manufacturing Integration

We accurately transform detailed steel project outputs created in softwares. Whether it’s factory buildings or complex industrial frames, our expertise in welded constructions guarantees perfection in the final product.

Capacity and Process Diversity

Thanks to our extensive machinery and equipment, we can efficiently process a wide range of steel profiles, from large-span beams to heavy load-bearing columns, at high volume and speed.

Aldem Çelik provides not only a reliable steel structure supplier but also a manufacturing partner supported by international quality certifications and fully committed to project delivery schedules.

Metal Fabrication & Welded Structures

Certified Steel Structures – ISO 3834-2 & EN 1090 EXC4

Quality is the cornerstone of our design and manufacturing philosophy. This commitment is reinforced by our internationally recognized mandatory certifications.

Structural Integrity Assurance

All steel structure manufacturing is carried out under EN 1090-2 EXC4. This verifies top-level fabrication capability, especially for components subjected to high dynamic loads, such as wind turbine tower elements.

Critical Welding Quality

Under the ISO 3834-2 Quality Assurance System, every welding operation (MIG/MAG, TIG) is rigorously controlled. Our certified welding engineers implement WPS/PQR procedures according to customer specifications, ensuring the weld and the heat-affected zone (HAZ) maintain full performance.

Partnering with Aldem Çelik ensures that your steel structure projects benefit from international welding expertise, certified quality, and on-schedule delivery, achieving the highest level of service excellence.

What We Manufacture

Steel Buildings

Steel Roofs

Canopies

Building Walkways / Passages

Skylights

Load-Bearing Systems

Platforms

Our Manufacturing Capabilities & Technical Infrastructure

Raw Materials Used

Carbon Steel

Stainless Steel

Aluminum

Documents Required From Our Customers

Technical Specifications

Project & Engineering Drawings

Coating Requirements

Material Procurement

Material supply is carried out in compliance with 3.1 Mill Certificates (EN 10204).

All materials are procured according to international quality standards and delivered with full traceability documentation.

Systems & Certifications

ISO 3834-2

EN 1090-2 EXC4

Welding

MIG Welding (Metal Inert Gas)

TIG Welding (Tungsten Inert Gas)

Laser Welding

Submerged Arc Welding (Manual & Automatic)

Robotic Welding

All welding operations are performed by certified welders using advanced welding technologies.

Cutting Operations (Sheet & Profiles)

Fiber Laser Cutting (20 kW, 2500×6000 mm, 60 mm carbon steel capacity)

5-Axis Laser Cutting

Profile / Tube Laser Cutting

Band Saw Cutting

Laser Cutting

Water Jet Cutting (Outsourced)

Oxy-Fuel Cutting (Outsourced)

Plasma Cutting (Outsourced)

Guillotine Shearing

We offer high-precision cutting solutions for various material thicknesses and complex geometries.

Drilling

CNC Profile Drilling (up to 1000 mm profile size)

CNC Punching Machines

Magnetic Drill Operations

Drilling processes can also be performed directly on our sheet laser cutting and profile/tube laser cutting machines.

Bending & Forming

CNC Press Brake Bending (including 7-axis systems)

CNC Plate Rolling

Sheets and profiles of different thicknesses are formed accurately to the required geometry.

Press Operations

Hydraulic and eccentric presses are utilized with high-precision tooling for sheet metal forming applications.

Machining

High-tolerance components are produced using multi-axis CNC machining centers.

Depending on part size and machining requirements, additional operations can be performed at certified partner workshops.

Assembly & Marking

Assembly operations are carried out according to customer requirements.

Marking and labeling follow international standards.

Available options include: custom industrial labels, QR-code labels, cold stamping, and laser engraving.

Pre-assembly and test fitting can be performed at our facility upon request or when field conditions require it.

Surface Cleaning & Preparation

Sandblasting

Glass Bead Blasting

Steel Shot Blasting

Additional Processes:

Grinding

Edge Rounding

Surface Roughening

Deburring

These processes improve surface quality and ensure an optimal finish.

Coating

Hot-Dip Galvanizing

Electro-Galvanizing

Wet Painting (including C5-grade & fire-resistant coatings)

Powder Coating

Cathodic Electrophoretic Coating (KTL / E-coat)

Hard Chrome Plating

Thermal Spray Coating

We provide long-lasting corrosion protection and high-quality surface finishing solutions.

Packaging

Layout & Packaging Design

Packaging with ISPM 15 certified heat-treated pallets

Products are prepared for safe handling and transportation.

Loading

Loading operations are carried out using forklifts, overhead cranes, mobile cranes, and certified securing equipment.

Truck and container loadings are performed by trained professionals.

Logistics (Incoterms)

EXW

FCA

FOB

CIF

DAP

Quality Control Documentation & Processes

ITP (Inspection & Test Plan)

Welding Documentation

Inspection Reports

NDT Tests:

VT – Visual Testing

PT – Penetrant Testing

MT – Magnetic Particle Testing

(Performed by our certified in-house team.)

UT & RT

(Accredited third-party laboratories perform additional tests required by specifications.)

Traceability Documentation

While general traceability is applied to every product, full, project-specific traceability is implemented upon client request or project scope requirements.