Dayanıklılığın, teknolojinin ve mühendisliğin kesişim noktasında: Aldem Çelik.

Aluminium Fabrication

- Home

- Aluminium Fabrication

Aluminium Fabrication

Precision Engineering and Advanced Production Technologies in Aluminum Fabrication

Precision Engineering and Advanced Production Technologies in Aluminum Fabrication

Aldem Çelik combines engineering precision with advanced manufacturing technologies in aluminum fabrication. Through welded aluminum structures, press-formed components, and high-accuracy part production, we deliver tailored solutions that meet the technical requirements of various industrial sectors.

Welded Aluminum Fabrication

- For applications requiring high strength, low weight, and corrosion resistance, we utilize TIG (Argon) and MIG welding technologies.

- All welding operations are carried out by certified welders in compliance with EN ISO 3834 and EN 1090 standards.

- Robotic welding systems and precision fixturing methods ensure repeatable quality and consistently clean, aesthetic weld beads.

Press Forming and Component Manufacturing

- During aluminum forming processes, Aldem Çelik operates high-tonnage press lines supported by CNC-controlled production systems.

- Our press forming capabilities provide exceptional accuracy in the serial or project-based production of aluminum plates, profiles, and custom-geometry parts.

- With CAD/CAM-assisted engineering workflows, customer-specific designs are produced with guaranteed dimensional precision and surface quality.

Surface Treatments and Coating Applications

In the final stage of production, high-quality surface treatments are applied to enhance both the aesthetic appearance and environmental durability of aluminum components:

- Electrostatic powder coating

- Industrial wet-paint systems

- Anodizing (eloxal) and chemical surface treatments

All coating applications are performed in accordance with customer specifications and verified through surface preparation checks, coating thickness measurements, and adhesion tests.

Quality and Reliability

- Quality, safety, and traceability are prioritized throughout all manufacturing processes.

- Each product undergoes mechanical testing, visual inspection, and surface measurement before shipment.

- Aldem Çelik operates with a commitment to high-quality production, engineering capability, and reliability in aluminum fabrication.

What We Manufacture

Aluminum Tanks

Aluminum Machine Bodies & Chassis

Machine Equipment Cladding Plates

Load-Bearing / Structural Systems

Silencers

Coolers / Heat Exchangers

Façade Panels & Components

Aluminum Platforms

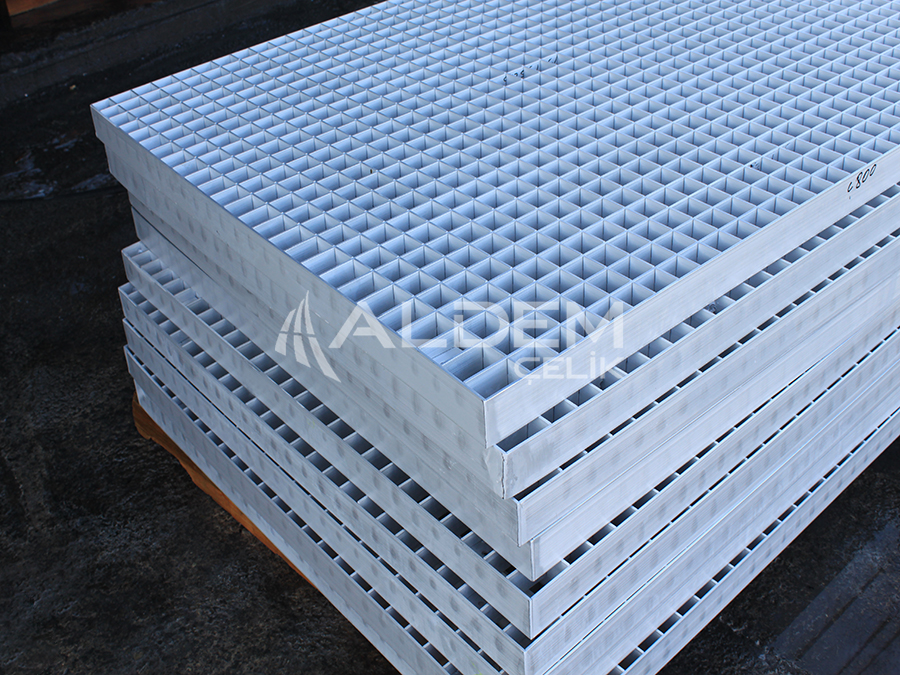

Aluminum Gratings

Project-Based Aluminum Products

Our Manufacturing Capabilities & Technical Infrastructure

Documents Required from Our Customers

- Technical Specifications

- Project and Technical Drawings

- Coating Requirements

Material Supply

Aluminum materials compliant with 1000 Series, 5000 Series, and 6000 Series standards are supplied.

All materials are procured in accordance with quality standards and delivered with full traceability documentation.

Welding

- MIG (Metal Inert Gas) Welding

- TIG (Tungsten Inert Gas) Welding

- Submerged Arc Welding (Manual & Automatic)

- Robotic Welding

All welding operations are performed by certified welders using advanced technology equipment.

Cutting Processes (Sheet & Profiles)

- Laser Cutting (20 kW, 2500 × 6000 mm, 60 mm carbon steel cutting capacity)

- 5-Axis Laser Cutting

- Profile and Tube Laser Cutting

- Saw Cutting

- Guillotine Shearing

High-precision cutting solutions are provided for various material thicknesses and geometries.

Drilling

- CNC Punch Press Machines

- Drilling operations can also be performed on our sheet laser cutting and profile/tube laser cutting systems.

Bending & Forming

- CNC Press Brake Bending (including 7-axis capability)

- CNC Plate Rolling

Sheet metals and profiles of different thicknesses are formed into the required shapes with precision bending machines.

Press Operations

Hydraulic and eccentric presses are used to provide high-accuracy sheet metal forming services with precision tooling.

Machining

High-tolerance parts are manufactured using multi-axis CNC machining centers.

Depending on part size or process requirements, machining operations may also be carried out in qualified external workshops.

Assembly & Marking

Assembly operations are performed based on customer requirements.

Marking and labeling are completed in accordance with relevant standards. Optional marking methods include:

- Custom printed labels

- QR code labels

- Cold stamping

- Laser engraving

Pre-assembly or trial assembly can be performed at our facility when required or when field conditions involve operational risk.

Surface Cleaning & Preparation

- Sandblasting

- Grinding

- Edge Rounding

- Surface Roughening

- Polishing

Coating

- Wet Painting (including C5 class and fire-resistant coatings)

- Powder Coating

- Anodizing

Packaging

- Layout and Packaging Design

- Packaging using ISPM 15 certified, heat-treated and marked pallets

All products are prepared for safe transport prior to shipment.

Loading

Safe loading operations are carried out using forklifts, cranes, mobile cranes, and securing equipment.

Truck and container loading is performed by experienced personnel.

Logistics

- EXW

- FCA

- FOB

- CIF

- DAP

Quality Control Documents and Procedures

- ITP (Inspection and Test Plan)

- Welding Documentation

- Inspection Reports

NDT Tests:

VT – Visual Testing

PT – Penetrant Testing

MT – Magnetic Particle Testing

(Performed by our certified in-house team.)UT & RT

(Accredited third-party laboratories perform additional tests required by specifications.)

Traceability Documentation

While general traceability is applied to every product, full, project-specific traceability is implemented upon client request or project scope requirements.