Dayanıklılığın, teknolojinin ve mühendisliğin kesişim noktasında: Aldem Çelik.

Platform Gratings

- Home

- Platform Gratings

Platform Gratings

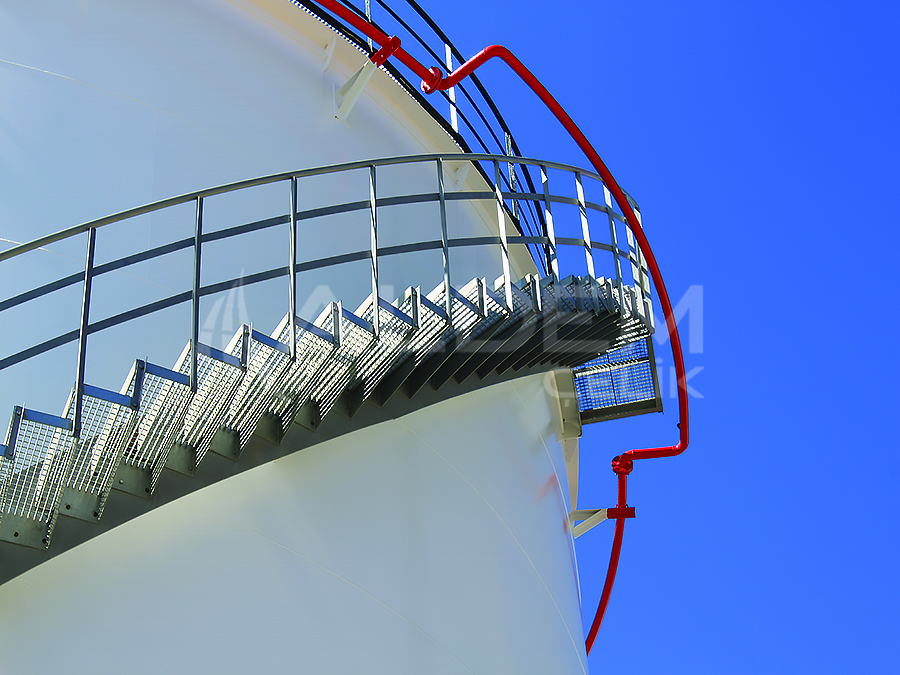

Platform Grating and Industrial Walkway Solutions

Platform Grating and Industrial Walkway Solutions

Aldem Çelik is one of the most experienced manufacturers in the field of platform gratings, with expertise dating back to 1984. We produce high-load-bearing gratings for industrial flooring applications. Our steel bars or rods are manufactured by pressing or welding on specialized machinery.

Manufacturing Techniques & Material Selection

Grating Types: Our production process includes “Half-Lattice”, “Full-Lattice”, and “Swaged Bar” type gratings.

Raw Materials: We utilize carbon steel, aluminum, and stainless steel as raw materials; the material and surface type are selected based on the specific application area.

Surface Finishes: Surface options include notched (anti-skid) and plain surfaces. The notched structure is preferred for areas with a high risk of slipping.

Surface Coating and Protection

Primary Protection: The most common coating for carbon steel platform gratings is hot dip galvanizing, which complies with the DIN EN ISO 1461 standard.

Other Options: Electro-galvanizing or optional paint coatings are also available for indoor applications. However, these may not be as protective as hot dip galvanizing in outdoor environments.

Usage Areas

Platform gratings are utilized across many different sectors, including:

Industrial facilities, power plants, and treatment plants

Marine industry, port facilities, and ship platforms

Floor decking, stair treads, and trench covers

Racking systems, walkways, and maintenance platforms

Advantages

High Load-Bearing Capacity: Ensures safe standing even under heavy loads.

Slip Resistance: Achieved through notched surfaces and suitable mesh design.

Easy Assembly: Manufacturing is possible in custom dimensions and forms tailored to the project.

Longevity: Durable against external conditions with the correct material and coating.

Why Aldem Çelik?

As Aldem Çelik, we control the entire process—from raw material selection to surface coating—in platform grating production, offering solutions tailored to specific size, material, and application requirements. This makes us a reliable partner for both standard and project-based industrial grating applications.

Gratings by Application Area

Walkway Platform Gratings

Stair Tread Gratings

Trench/Channel Gratings

Drainage Gratings

Floor Decking Gratings

Facade Gratings

Ventilation Gratings

Machine Platform Gratings

Service Deck Gratings

Bridge Platform Gratings

Racking Gratings

Railing Gratings

Decorative Architectural Gratings

Heavy-Duty Gratings

Circular Gratings

Framed Assembled Gratings

Trailer Bed Gratings

Maintenance Platform Gratings

Paint Booth Gratings

Drip Pan Gratings

Our Manufacturing Capabilities & Technical Infrastructure

Technical Specifications of Platform Gratings

Platform gratings are modular load-bearing elements created by joining steel, stainless steel, or aluminum load-bearing bars with cross rods. Each grating panel is custom-designed based on load, span, visual, and usage conditions.

Manufacturing Methods

Press-Welded Grating:

Load-bearing bars and cross rods are joined under high pressure. This method provides high rigidity and homogeneous load distribution.

Welded Grating:

Load-bearing bars and cross rods are joined using the electric resistance welding method. This is preferred for floors and platforms operating under heavy loads.

Material Properties

| Material Type | Quality Standard | Characteristics |

| Carbon Steel | S235JR (EN 10025-2) | High strength, economical solution |

| Stainless Steel | AISI 304 / AISI 316 | High corrosion resistance, suitable for hygienic areas |

| Aluminum | EN AW-5754 / EN AW-6063 | Lightweight, aesthetics, and oxidation resistance |

Surface Types

Plain Surface: For general industrial applications.

Notched (Anti-Skid) Surface: For areas requiring non-slip properties.

Coated Surface: Corrosion resistance is enhanced with hot dip galvanizing.

Dimensions and Tolerances

Load-bearing bar width: 20–100 mm

Load-bearing bar thickness: 2–5 mm (Standard mm is given. Thickness can be increased. Non-standard sizes can be produced.)

Grating bar spacing: 30–100 mm (Made in standard dimensions.)

Panel dimensions: Production in custom sizes based on the project.

Load calculations are performed according to DIN 24537 and EN ISO 14122-2 standards.

Load-Bearing Capacity

The load-bearing capacity of platform gratings is determined by the bar cross-section, grating spacing, and panel span.

Aldem Çelik performs load analyses using standard tables, ensuring the optimization of the grating type and section suitable for the intended use.

Surface Coating Standards

Hot Dip Galvanizing: Compliant with the DIN EN ISO 1461 standard, with an average coating thickness of 70–100 µm.

Passivation and Sandblasting: Provides surface protection for stainless steel or aluminum gratings.

Assembly and Application

Platform gratings are secured to the main construction using bolt-connected clamp systems.

Clamp material: Galvanized or Stainless Steel

Custom connection types and designs can be produced.

Standards and Compliance

All production and quality control processes are carried out according to the following standards:

EN ISO 9001 – Quality Management System

EN ISO 3834 – Welding Quality Standard

EN 1090 – Execution of Steel Structures Compliance

DIN 24537-1/3 – Steel Grating Dimensions and Tolerances

Technical Documents

under construction..